Metal Additive Manufacturing

Metal additive manufacturing is the process of

creating a 3D object from a CAD model by building

it up from metal powder, layer by layer. This

technology can produce complex shapes that

are not possible with traditional manufacturing

methods.

The most common industries to commission

production of specific components are aerospace,

defense and transport, so reducing the chances

of oxidization of the metal during the build

process is essential as this can lead to a build

failure, stress test failure or also a density test

failure due to low quality standards. Interstitial

absorption of any oxide embrittles the weld and

may render the component useless.

Why Additive Manufacturing versus traditional methods?

This technology can reduce material waste, the amount of steps in the production process,

and decrease the amount of distinct parts in the assembly process by a significant amount.

The future adoption of this technology in many

industries depends on the measurement and

control of oxygen concentration within the

manufacturing process.

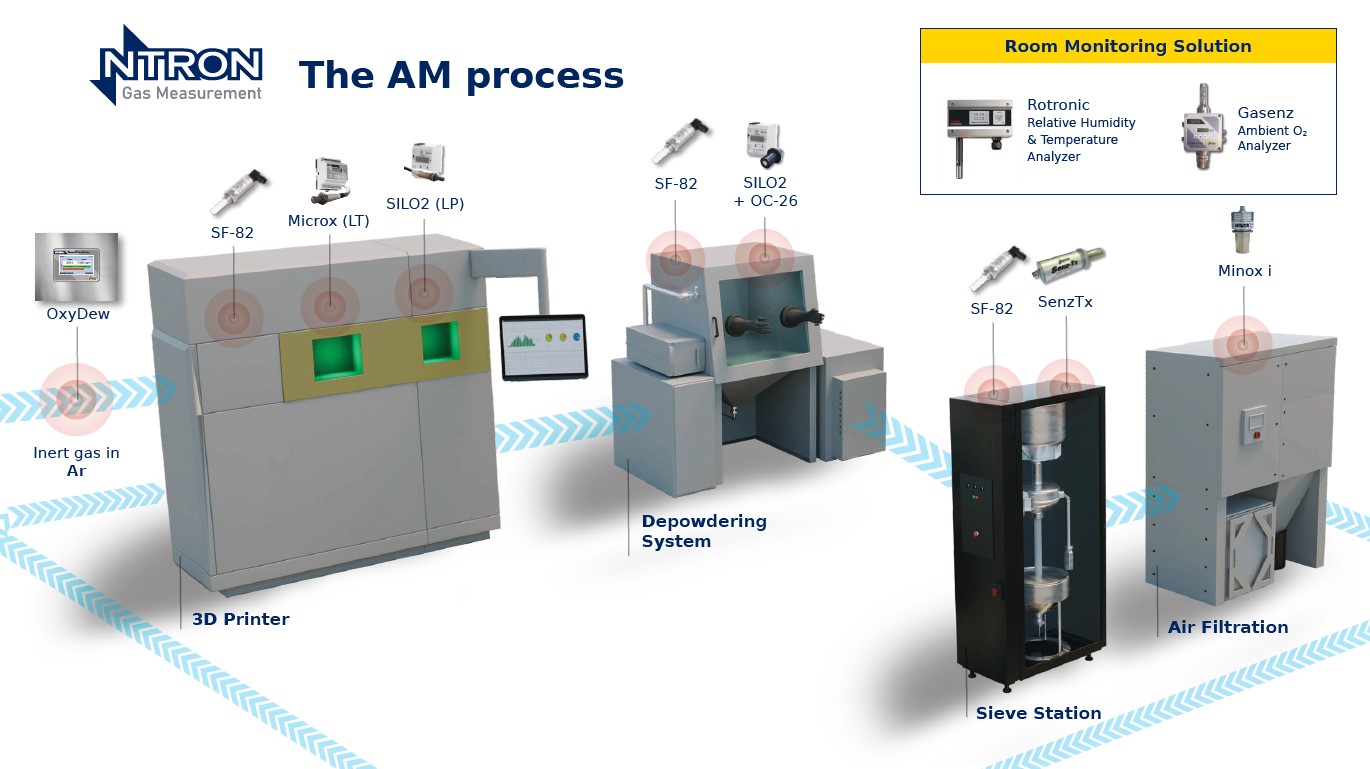

The Ntron Solution

Ntron has developed an in-line SIL 2 rated Oxygen Analyzer designed specifically for harsh applications within the additive manufacturing industry.

SIL-02 Oxygen Analyser

The SIL2 rated oxygen analyzer has been developed specifically for

the measurement of oxygen for safety critical application within the

chemical and pharmaceutical industry.

Learn More

Microx Oxygen Analyser

The Ntron OxyTx oxygen analyzer is designed to use with Ntron’s range of chemically resistant

oxygen sensors which are suitable for use in monitoring oxygen on

harsh chemical applications.

Learn More

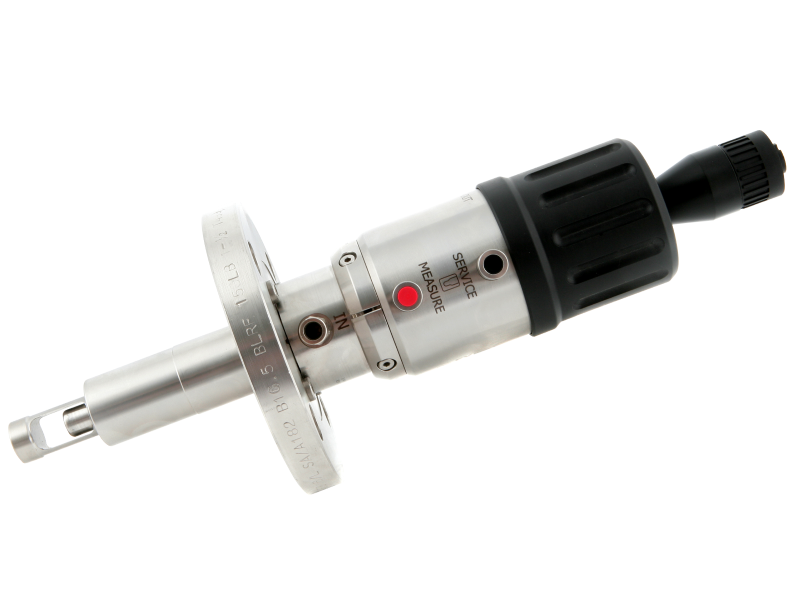

OxyExtract Oxygen Analyser

The OxyExtract Range of IECEx/ATEX approved retractable InLine Oxygen Sensors along with the OxyOne Analyzer and ACCU

Calibration unit, provide a cost effective solution to meet your

process safety requirements.

Learn More

OxyProbe Sensor

The long life solid state Oxyprobe 200 is designed for In-Situ measurement of Oxygen concentration on harsh Chemical Applications within the Fine Chemical and Pharmaceutical industry.

Senz-Tx Oxygen Sensor Transmitter

The Senz-Tx is a highly reliable and cost-effective transmitter with

a linearized 4 to 20 mA output. It has a minimum detection range

of 0-10 ppm up to 0-96% Oxygen.

Learn More

OxyOne Oxygen Analyser

OxyOne has been designed specifically for the monitor and

control of inert process applications. It is capable of accepting two

separate oxygen sensors and it is designed to interface directly

with Ntron’s inline or extractive sampling systems.

If you are interested in oxygen measurement in additive manufacturing and need more information on these instruments, view our products here

Ready for the next step? Please contact our Sales team for more information.

If you have a specific application not covered, please complete our Application Questionnaire and our Sales team will be in touch shortly.

Brochure

Fail Safe Oxygen Measurement in Additive Manufacturing

-

Applications

- • Air Separation

- • Fail Safe Oxygen Measurement

- • Oxygen Measurement in Containment Solutions

- • Gas Measurement for Gloveboxes

Contact Us

CALL +353 46 907 1333

EMAIL sales@ntron.com